Innovative. Creative. Capable.

Custom Thermoforming at its Best

Welcome to ThermoPro

We are a plastics thermoforming manufacturer located in the metro Atlanta, Georgia area. We specialize in heavy gauge vacuum forming, pressure forming, drape forming, plastic fabrication and secondary assembly.

Thermoformed plastics are a viable alternative to injection molded plastics, particularly for larger parts and smaller quantity requirements. Our expertise enables us to choose the materials best suited for your application. Tooling costs for thermoformed parts are often a lot less than for injection molded parts, thus significantly reducing up front costs.

Pressure forming can create finely detailed parts of very high quality. Drape forming is a very cost effective way to produce plastic parts of relatively simple design. And our experience with plastic fabrication and secondary assembly gives us the ability to completely finish parts from beginning to end

ThermoPro, has been recognized as a top 10 supplier for Yamaha Motors!

Our commitment to quality, reliable turn-around times, and affordable pricing can give your company the same competitive edge.

Call today for a free quote from the Southeast’s premier thermoformer.

WHY CHOOSE THERMOPRO?

Innovative. Creative. Capable.

We provide:

- Consistently high quality custom made products

- Superior service, with on time delivery

- Experience with a multitude of plastics, including ABS, polystyrene, polyethylene, polypropylene, TPO, polycarbonate, acrylic, PETG and others

- Experience in running highly cosmetic and clear plastics

INNOVATIVE SOLUTIONS

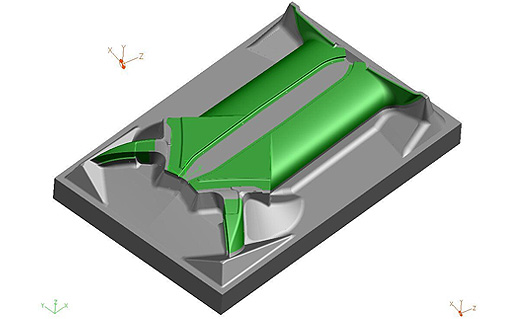

ThermoPro employs the latest technology to provide a more efficient process from design to production. These innovative processes and technologies solve your particular thermoforming and plastic fabrication needs.

- Heavy gauge vacuum forming and pressure forming

- Heat bending

- Plastic fabrication

- 3 & 5 axis CNC routing

CREATIVE & CAPABLE

Our Engineering and Technical Team can devise creative ways to enhance product design, drive down costs and improve quality. Let us help you find a solution.

- Highly educated and skilled personnel

- Proactive communication

- State-of-the-art technology

- Unsurpassed customer service

MEET THE THERMOPRO TEAM

We are a team of highly qualified professionals, dedicated to providing custom high quality thermoforming solutions, with competitive prices and unsurpassed customer service. Please contact us with requests for information or for a custom quote.

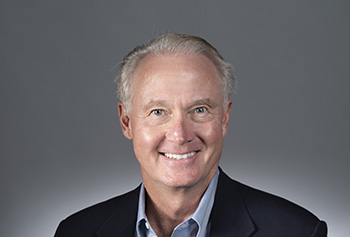

Greg Weigle

Greg Weigle has been the CEO & President of ThermoPro since June 30th, 2017. He has been involved with the company since 2003 as an outsourced CFO. Greg brings broad experience to the company acquired over 17 years of serving multiple companies in multiple industries in the CFO capacity.

Greg has been active in his community through coaching, as director of several sports clubs and through volunteering with his church. He is married and has 4 children.

Gloria Bell

Gloria Bell has been running our offices since 2017. Your initial point of contact coming in the front door, Gloria handles our HR, AP, and helps with customer service. By keeping everything on the back end running smooth, she helps the rest of us focus on quality production and a quick turnaround for your project.

Lynn Carroway

Lynn Carroway has been in the plastics industry since 1992 and is an expert in all aspects of thermoforming. Lynn will walk your project through the process from quoting to on-time shipping, making sure that tooling and finished parts meet specifications and function as designed at every step.