What happens when you present a FUN challenge to a group of talented manufacturers? They might just create the perfect prize wheel. Though it may seem we have always been on top of our game (ha!) the truth is, our classic prize wheels we sell today had a humble origin.

So, what goes into makings the perfect prize wheel?

![]()

This beauty (above) is the first-ever prize wheel made at ThermoPro. Today, our prize wheels and games are made for anyone to enjoy. But in 2002, we created this wheel as a way to recognize our employees and celebrate milestones. Our technical director, Mike Sinette, constructed the stand and wheel out of spare materials leftover in the shop. The company owners decided on the prize values the employees could spin for.

Our employees enjoyed the original wheel for two years, celebrating birthdays, work anniversaries and other milestones. In 2004, a business associate asked during a spin, “Why don’t you manufacture them?”, it was a good question. We took his suggestion to heart, and began work on the first prototype.

Product Development

The design process for the first production wheel spanned a period of several months and involved many different variations. Not only were we challenged to make a wheel that was exciting and fun to look at, but it also had to be lightweight, durable, and customizable.

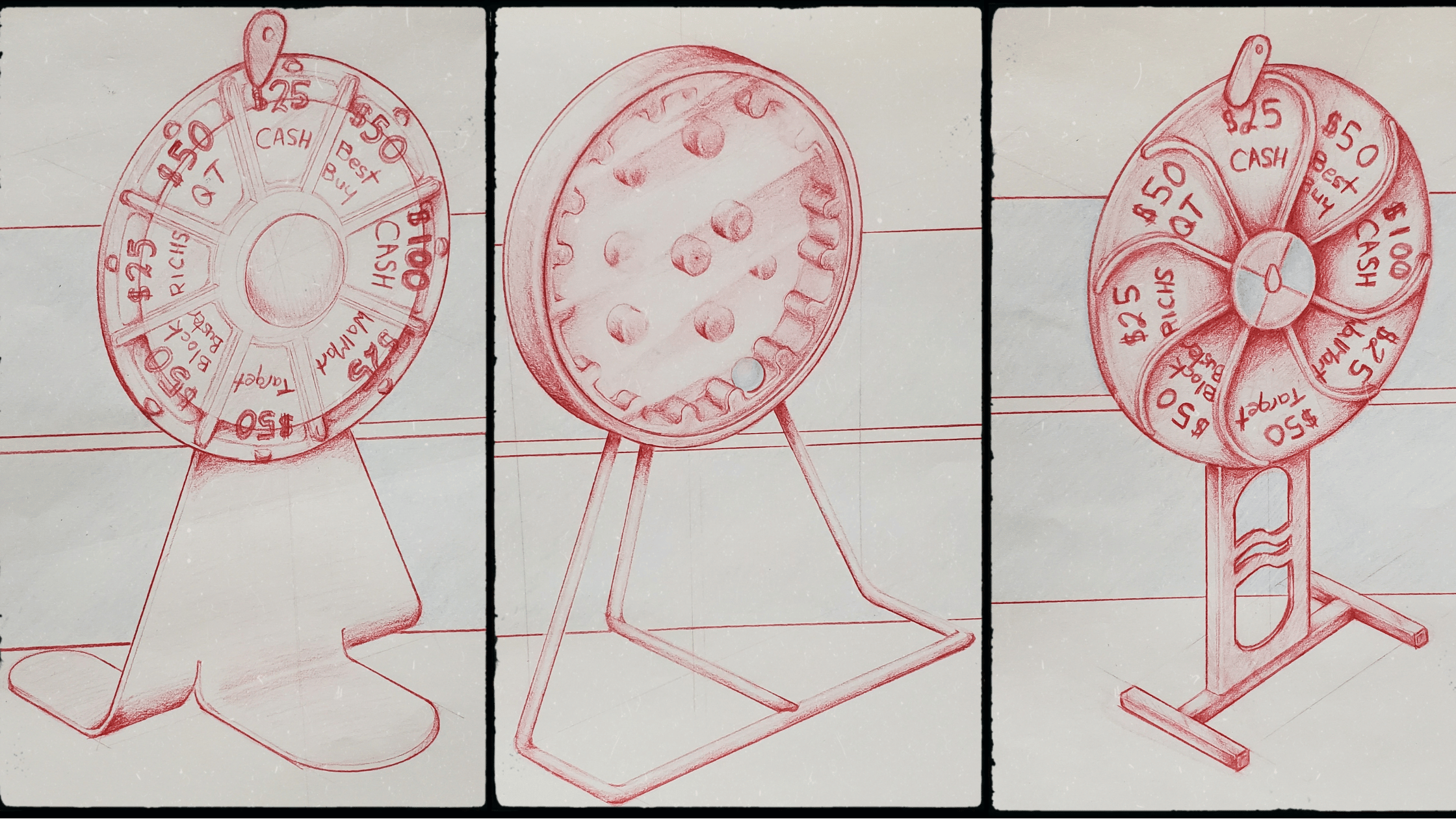

Here are a few of the design ideas for the first wheel:

With the initial steps of the design out of the way, the owners and technical team set an ambitious goal – have a wheel ready-to-spin at a promotional product trade show in Las Vegas. However, the show was only a few months away!

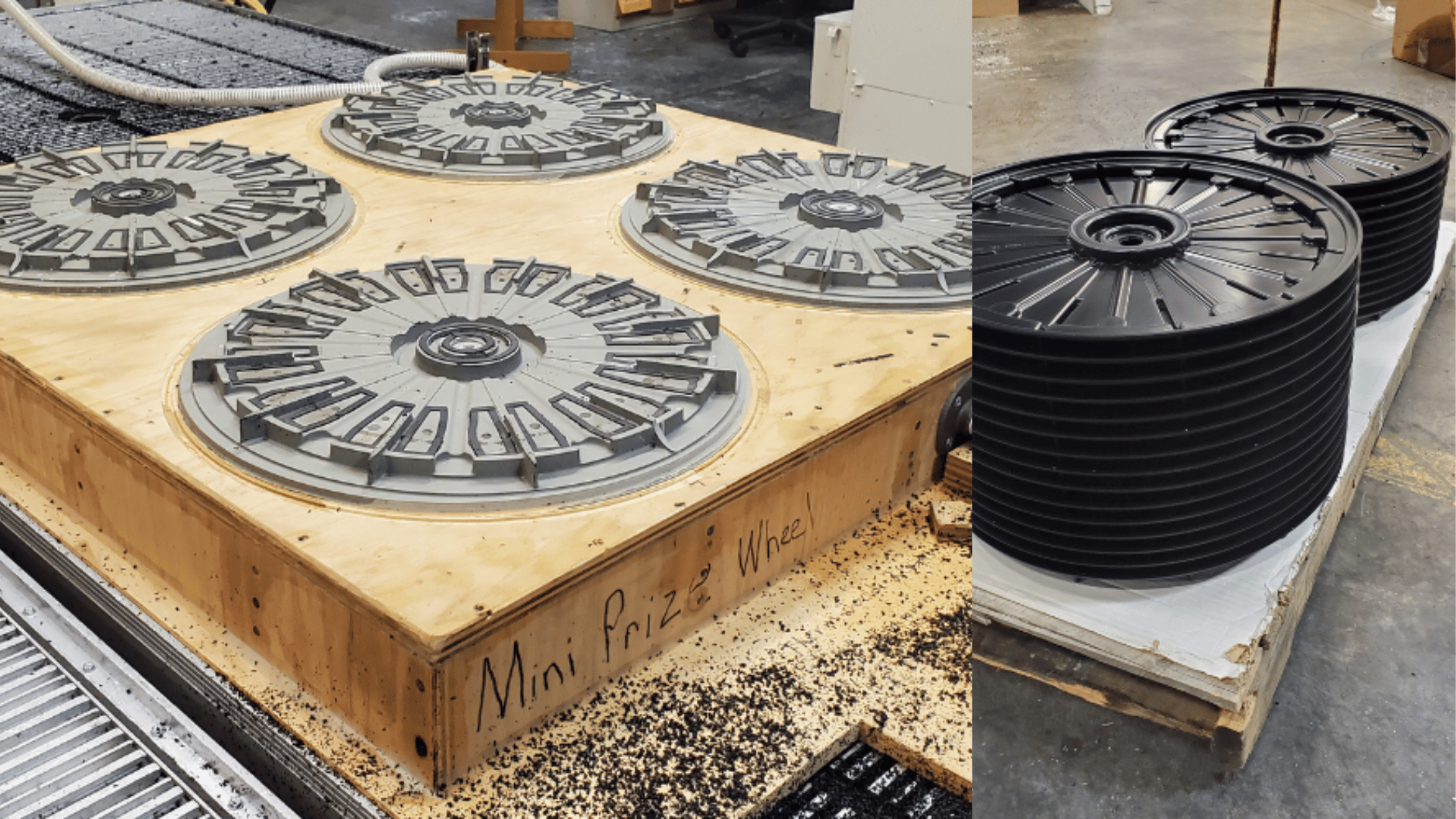

Our team got right to work. First, they sent over renderings for the wheel front to a mold maker. Once the mold was made and could be fitted to our thermoforming machines, we would be able to form the front component of the prize wheel.

In the meantime, our team experimented with different stand concepts. The first stand prototype was made from the metal legs of an office chair, which were cut into pieces and welded together. While this first stand was heavy and difficult to transport, it was durable and the perfect height for tabletop use.

After receiving the mold from the mold maker, it was crunch time. Our team had less than a week to vacuum form and CNC route the wheels, attach them to stands, and make sure they were balanced for the perfect spin. Our engineering team arrived to work at 2am on the Tuesday before the deadline, in order to have the best wheel possible ready to go that Friday.

Throughout the week, the team worked on forming the wheels, removing any excess materials, and making sure the final product was functional and uniform. When the Friday deadline approached, the team finished the user tests and wheels right in the nick of time. Off to the show they went.

Our prize wheels were a huge hit at the show! This encouraged the owners to kick off full-time production of prize wheels. Up until this point we had only manufactured one type of product, so this was a new and exciting shift for ThermoPro.

Going to the show was a great opportunity to receive feedback and improve on our product. We also made some great connections there like the metalworkers who eventually helped us create our current adjustable tripod stands.

Over the years we have perfected our wheels making the manufacturing process more efficient as well as more cost effective. The tripod stand we created in 2004 and a wheel redesign in 2011, gives us the wheels we currently manufacture and sell today!

How do we make our wheels today?

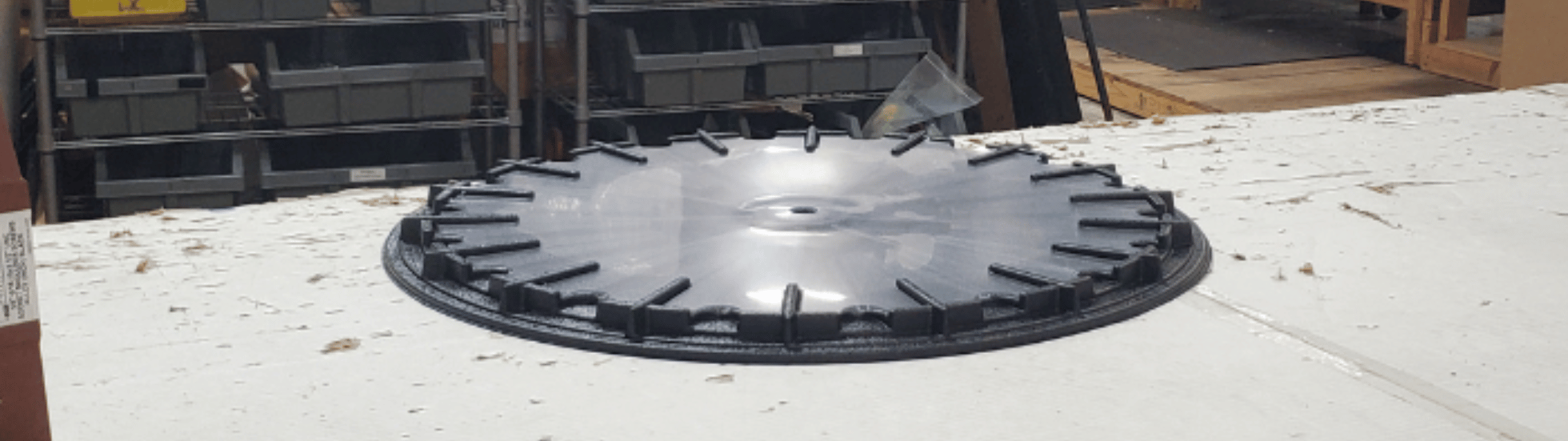

First, we place sheets of Acrylonitrile-Butadiene-Styrene (ABS) plastic on one of our wheel molds. We have several different mold sizes, depending on what size wheels we need. The ABS material is vacuum formed on the thermoforming machine, before the formed part is moved to our routing station. Routing removes all of the excess plastic surrounding the wheel, and ensures each wheel is uniform.

Once the wheel is routed, a clear panel of Polyethylene terephthalate glycol (PETG) is snapped into place on top, creating the slots for prize cards.

The last step in prize wheel assembly is attaching the wheel to the stand, which differs based on the size and type of wheel.

Every wheel we manufacture undergoes strict quality control to ensure consistency, balance, and durability. With the amount of time, innovation, and passion we’ve put into our line of prize wheels, we want to ensure every customer has a satisfying and FUN experience.